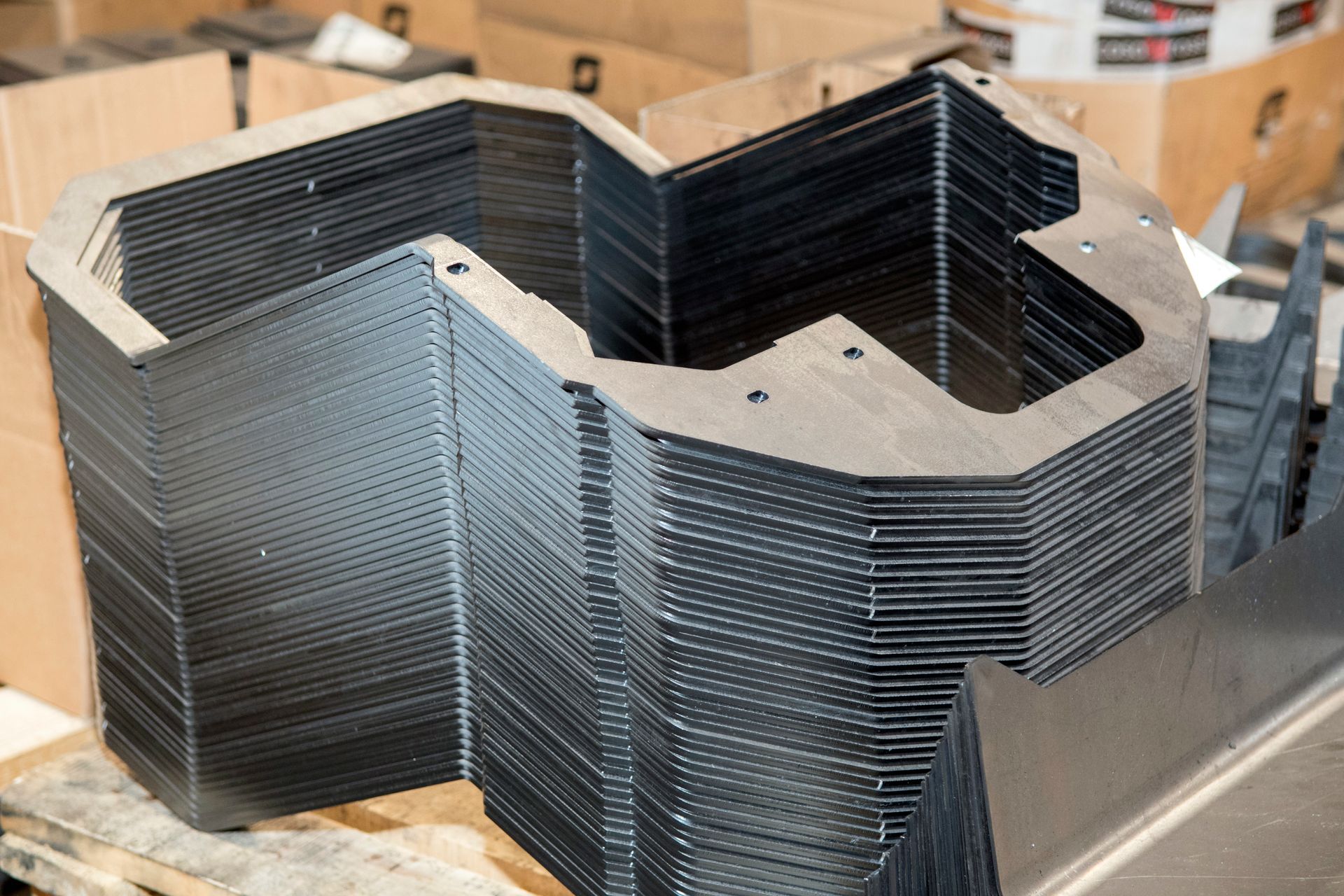

Bending sheet metal

Ense s.r.l. provides a range of services for its customers, including sheet metal bending, a processing technique that involves permanent deformation through bending operations.

Metals have a "neutral fibre" within them which can be deformed without stretching or contracting. The success of the operation is entirely based on the different properties of the metals selected. These must in fact be sufficiently plastic not to create cracks in the vicinity of the bend.

For tasks of this kind it is necessary to rely on highly experienced groups, such as Ense s.r.l., who are able to determine, and if necessary correct, springback. Ense provides the customer with quality, a robust structure and state-of-the-art electronic solutions, such as a high-performance bending machine to guarantee high performance.

Specifications

Full length: 6,200 mm

Groove: 1,000 mm

Tonnes: 1,000 (nominal)

Point load: 500 tonnes/m

Machinery

- N° 1 CMP: 50 tonnes x 1,250 mm

- N° 1 SCHIAVI: 125 tonnes x 1,250 mm

- N° 1 CBC: 300 tonnes x 3,000 mm

- N° 1 SCHIAVI: 400 tonnes x 5,000 mm

Air bending

Using a higher punch you can carry out air bending, pressing the sheet into a lower, V-shaped die. There are a total of three points of contact between the surface to be bent and the machine, two on the die and one on the punch. The technicians then determine the bending angle, based on the depth to which the punch descends.

The procedure takes into account over-bending, a phenomenon that literally consists of a bend greater than necessary, in order to compensate for springback, so as to obtain the selected angle. The technical department at Ense s.r.l. will always be able to opt for the best choice, with air bending offering various advantages, from the lower force required to the possible bending of thick sheet metal.

Coining and flattening

The coining operation requires the use of a punch, which fully presses the plate, reaching the hollow bottom of the bottom die. It is essential that the die and punch are inclined to the same angle, thereby completely eliminating springback. This system is mainly chosen when bending 90° angles, on thin sheet metal. This option guarantees precision, as well as achieving smaller angles than air bending.

There are two steps in the flattening process. The first is a pre-bend, between 26 and 35° (with bending in air). The second is a partial or total flattening of the sheet. This provides rigidity, edge protection and elimination of free edges.

New bending machine: Trubend 5320

World's most successful bending machine. From programming to tooling to actual bending, it is unrivalled in terms of productivity:

- quiet and fast

- the on-demand servo drive operates energy-efficiently, quickly and quietly

- angle measuring systems from the ACB family, making even the first piece come out perfect

- flexible, die to six-axis backgauge for maximum freedom of application

CHARACTERISTICS

- pressure force: 3,200 kN

- clamping length: 4,420 mm

- free passage of mast: 3,680 mm

- useful opening: 1,615 mm

- outreach: 420 mm

- user interface: Touchpoint TruBend

- speed of Y-axis working phase (option): 25 mm/s

Cutting

Sheet metal and metal cutting of various sizes and thicknesses. Water jet, laser, plasma and oxy cutting.

Contact us

Any questions? We are here to help you. Send us a message and we will reply.