Laser cutting

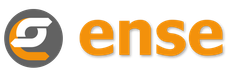

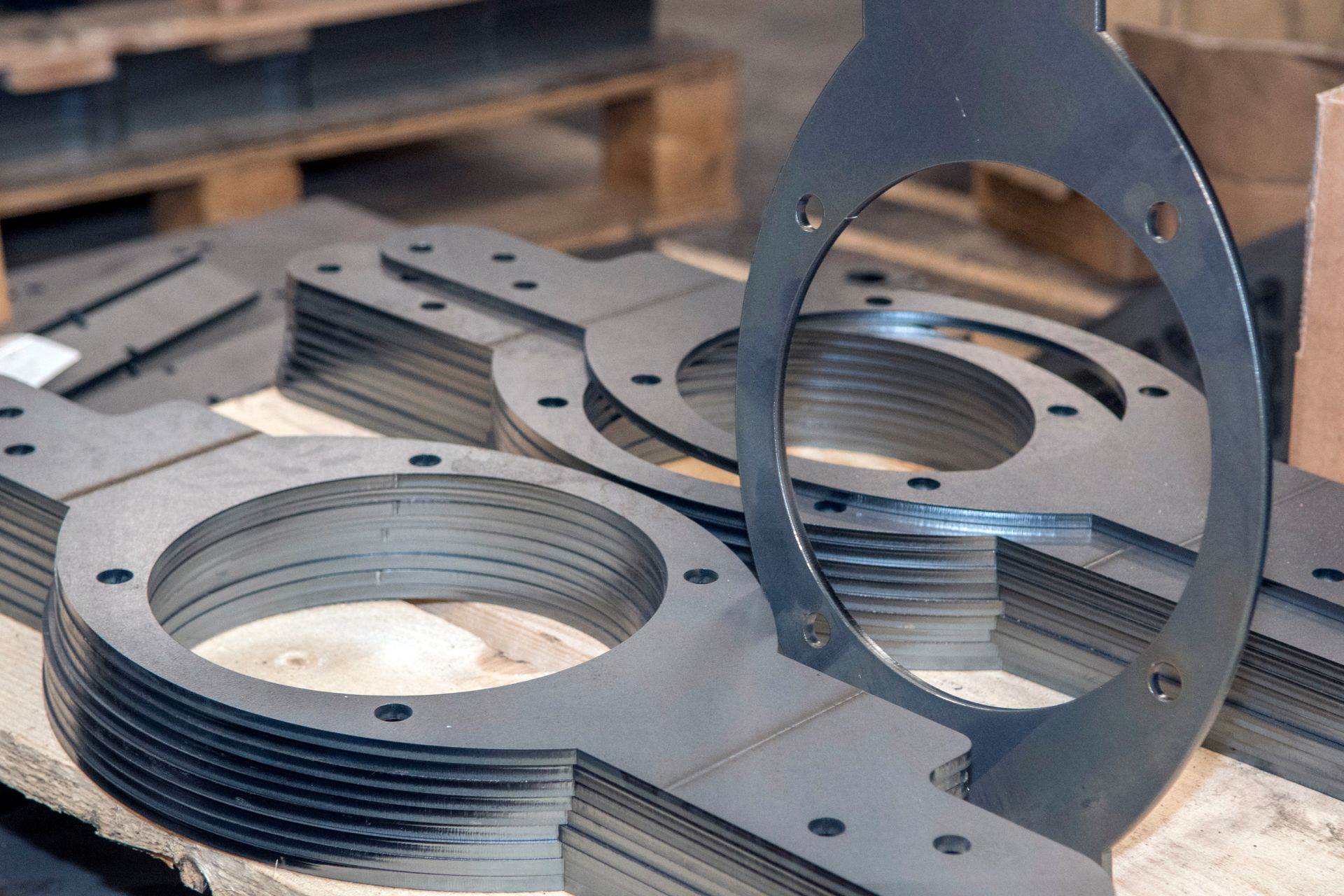

Laser cutting allows for high-speed cutting of sheet metal of different thicknesses

Fast, precise cutting

Ense specialises in sheet metal cutting and bending, using the most innovative cutting technologies and offering its services to companies throughout Northern Italy.

Our company is also at the forefront of the laser cutting business, thanks to state-of-the-art machinery that allows for high-speed cutting on both thick and thin sheets, such as 25 mm steel.

Laser cutting is a processing technique that can be applied to many sorts of materials and shapes. The advantages of laser cutting include its ability to cut even small geometric shapes with maximum precision. Compared to mechanical cutting, laser cutting is also sharper and has almost no contamination.

WOrking area

X axis: 6,000 mm

Y axis: 2,000 mm

Z axis: 115 mm

Max. piece weight: 2,800 kg

maximum width

Structural steel: 25 mm

Stainless steel: 25 mm

Aluminium: 15 mm

MAXIMUM speed

On parallel axes: 200 m/min

Simultaneous: c. 300 m/min

Precision

Min. workable length: 0.01 mm

Deviation from starting position: +/- 0.1

Max. guaranteed power: 5,000–6,000 W

Laser cutting of various materials

The machines used for laser cutting consist of a cutting head, a system of axes or a robotic arm, a shielded structure to protect workers from accidents, and a digital control for the entire process.

Laser cutting machines can be used either on their own or within production lines consisting of automatic storage, loading and unloading systems or in combined lines.

Ense has machines that can cut aluminium up to a thickness of 15 mm and stainless and structural steel up to a thickness 25 mm, with a guaranteed maximum power of 5,000–6,000 W.

Contact us

Any questions? We are here to help you. Send us a message and we will reply.